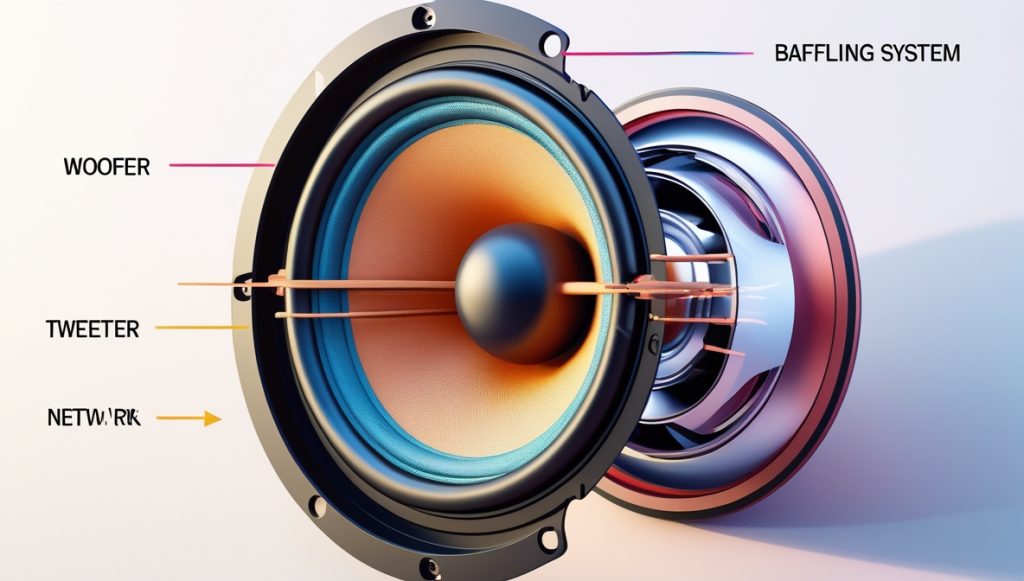

Building a high-quality speaker involves much more than just selecting the right drivers and crossover network. A crucial, often overlooked element is the internal baffling. The baffle, the internal structure of your speaker enclosure, significantly impacts the sound quality.

Common materials for speaker baffling include MDF (Medium-Density Fiberboard), plywood, hardwoods, fiberglass, polyester batting, and acoustic foam. Dense materials like MDF and hardwoods provide rigidity and control resonances, while porous materials like fiberglass and polyester batting absorb sound energy and reduce internal reflections. The best choice depends on your budget, desired acoustic properties, and the specific frequency response you want to achieve.

This beginner’s guide explores the various materials you can use for speaker baffling, examining their acoustic properties and how they contribute to the overall performance of your speaker system. We’ll delve into the science behind baffling and guide you through the process of selecting and implementing the best material for your project.

Contents

- Understanding Speaker Baffling Needs

- Common Baffling Materials Overview

- Acoustic Properties of Different Fillers

- The Role of Density in Baffle Design

- Dampening Vibrations: Material Choices

- Utilizing Synthetic Fillers Effectively

- Natural Materials for Speaker Baffling

- Balancing Cost and Acoustic Performance

- Optimizing Internal Speaker Airflow

- Testing and Refining Your Baffle Design

Understanding Speaker Baffling Needs

The primary function of speaker baffling is to control the sound waves produced by the speaker driver. Without a properly designed baffle, sound waves emanating from the rear of the driver interfere destructively with those from the front, resulting in a muddy, weak, and unbalanced sound. This interference is particularly problematic at low frequencies where wavelengths are longer. Therefore, the baffle’s design directly impacts the speaker’s frequency response and overall clarity.

Consequently, the ideal baffle material will minimize these unwanted interactions. It needs to be sufficiently rigid to prevent unwanted resonances and vibrations that can color the sound. Furthermore, the choice of material also influences the internal damping, affecting how effectively the baffle absorbs unwanted energy, preventing it from reflecting back into the speaker cabinet and impacting the sound. The correct baffle material is crucial for achieving a clean, accurate, and powerful sound.

Common Baffling Materials Overview

Several common materials find applications in speaker baffling, each with its own set of advantages and disadvantages. These include various types of wood, such as MDF (Medium-Density Fiberboard), plywood, and even solid hardwoods. Beyond wood, we also find synthetic materials like fiberglass, polyester batting, and acoustic foam. The choice depends on several factors, including the desired acoustic properties, budget, and the level of DIY experience.

Moreover, the choice of material often involves a trade-off between cost and performance. While some materials, like high-quality hardwoods, offer superior acoustic properties, they can be significantly more expensive than other options. Conversely, more affordable materials like MDF may require additional damping treatments to achieve comparable sound quality. Understanding these trade-offs is key to making an informed decision.

Acoustic Properties of Different Fillers

Different materials exhibit different acoustic properties. For instance, dense materials like MDF tend to be more rigid and less prone to resonance, leading to a tighter, more controlled bass response. However, they may not absorb as much internal energy as more porous materials. In contrast, materials like fiberglass offer excellent sound absorption but might introduce some slight coloration to the sound if not managed carefully.

Furthermore, the porosity of the material plays a crucial role. Highly porous materials, like acoustic foam, effectively absorb sound energy, preventing internal reflections and improving clarity. Less porous materials, on the other hand, reflect more sound energy, potentially leading to undesirable resonances. Therefore, understanding the acoustic properties of each material is crucial for selecting the optimal option for your specific speaker design.

The Role of Density in Baffle Design

The density of the baffling material directly impacts its performance. Higher-density materials, like dense MDF or hardwoods, are stiffer and less prone to vibrations. This rigidity translates to a cleaner, more accurate sound reproduction, especially in the lower frequencies. These materials are less likely to introduce unwanted resonances or coloration into the sound.

Conversely, lower-density materials, while often cheaper and easier to work with, are more susceptible to vibrations. These vibrations can lead to unwanted resonances and a less controlled sound. Therefore, when choosing a material, a balance must be struck between cost, ease of use, and the desired level of rigidity and acoustic control. The density of the material directly influences the overall sound quality.

Dampening Vibrations: Material Choices

Dampening unwanted vibrations is critical for achieving high-fidelity sound. Materials like acoustic damping mats or felt can be strategically placed inside the speaker cabinet to absorb internal resonances and reduce unwanted coloration. These materials effectively convert vibrational energy into heat, minimizing the impact of unwanted resonances on the sound.

Additionally, the use of constrained-layer damping techniques can be highly effective. This involves using a layer of damping material between two stiffer layers, significantly reducing the transmission of vibrations. This approach is particularly useful for reducing resonances in thinner baffle materials. The choice of damping materials should complement the chosen baffle material to optimize the overall performance of the speaker.

Utilizing Synthetic Fillers Effectively

Synthetic fillers like polyester fiberfill or acoustic foam offer several advantages. They’re relatively inexpensive, readily available, and easy to work with. Polyester fiberfill, for example, is excellent for absorbing midrange and high-frequency sound waves, reducing internal reflections and improving clarity. However, it doesn’t offer much in terms of structural rigidity.

Moreover, the strategic placement of synthetic fillers is crucial. Over-stuffing the cabinet can negatively impact the bass response, while insufficient filling can lead to unwanted resonances. Experimentation and careful placement are vital to optimize the performance of the synthetic filler. It’s often best to use a combination of materials to address different frequency ranges effectively.

Natural Materials for Speaker Baffling

Natural materials, such as various hardwoods or plywood, offer a different set of characteristics. Hardwoods, known for their density and stiffness, provide excellent rigidity and minimize unwanted resonances. This results in a tighter, more controlled bass response and an overall cleaner sound. However, they can be more expensive and challenging to work with than synthetic alternatives.

Furthermore, the grain orientation of the wood can affect the acoustic properties. Properly aligning the grain can enhance the stiffness and reduce unwanted vibrations. Plywood, with its layered construction, offers a good balance between stiffness and cost-effectiveness. Choosing the right type of wood requires considering both acoustic performance and the practical aspects of construction.

Balancing Cost and Acoustic Performance

The choice of baffling material often involves a trade-off between cost and acoustic performance. High-end hardwoods offer superior acoustic properties but come at a higher price. Conversely, materials like MDF or particleboard are more affordable but might require additional damping treatments to achieve comparable sound quality.

Therefore, careful consideration of your budget and desired sound quality is crucial. It’s often possible to achieve excellent results by combining less expensive materials with strategic damping treatments. For instance, using MDF as a base material and supplementing it with acoustic damping mats can provide a cost-effective solution without sacrificing significant sound quality.

Optimizing Internal Speaker Airflow

Internal airflow within the speaker enclosure significantly affects the bass response. While the baffle material itself doesn’t directly control airflow, its properties can indirectly influence it. For instance, a very dense baffle might restrict airflow slightly, potentially affecting the low-frequency performance. Careful consideration of the internal volume and porting (if any) is crucial for optimal bass response.

Consequently, the design of the internal bracing within the cabinet can also impact airflow. Overly restrictive bracing can negatively affect the bass. A balance must be struck between providing sufficient structural rigidity and maintaining adequate internal airflow to allow for proper bass reproduction. This often requires careful planning and potentially some experimentation.

Testing and Refining Your Baffle Design

Once you’ve constructed your speaker, testing and refinement are crucial steps. Use a measurement microphone and software to analyze the frequency response of your speaker. This allows you to identify any peaks or dips in the frequency response that may indicate unwanted resonances or other issues related to the baffle design.

Subsequently, based on the test results, you can make adjustments to the baffle design, including adding damping material, altering the internal bracing, or even experimenting with different baffle materials. Iterative testing and refinement are essential to optimize the performance of your speaker and achieve the desired sound quality. This process is crucial for achieving the best possible results.

Choosing the right material for speaker baffling is a critical step in building high-quality speakers. This involves understanding the acoustic properties of various materials, considering the trade-offs between cost and performance, and carefully managing internal airflow and vibrations. By following the guidelines outlined in this beginner’s guide and employing iterative testing and refinement, you can significantly improve the sound quality of your speaker system. Remember that experimentation and a willingness to learn are key to mastering the art of speaker building.